The casual crinkled look of linen is naturally beautiful. I have a crush on linen which I’ve written about before and believe it to be the most sustainable of all natural fibres. Just machine wash, shake and hang to dry and wear as is – and if you want a nice even crinkle, give it a short tumble-dry. I haven’t ironed linen for years – saving lots of energy and effort.

The casual crinkled look of linen is naturally beautiful. I have a crush on linen which I’ve written about before and believe it to be the most sustainable of all natural fibres. Just machine wash, shake and hang to dry and wear as is – and if you want a nice even crinkle, give it a short tumble-dry. I haven’t ironed linen for years – saving lots of energy and effort.

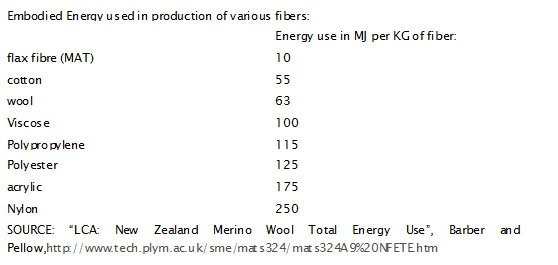

There is a sign (right) in one of Brisbane’s fabric stores (Spotlight) promoting the casual wrinkled look as being the way to wear linen these days. Hooray – hope it leads to more people wearing linen because based on the embodied energy information outlined below, linen is the most energy efficient fibre available. I’ve sourced this table from the O Ecotextiles website, which used an academic study done for the New Zealand Merino Wool Association as its original data.

Linen and cotton are plant fibres – linen made from leaves of the flax plant and cotton from the cotton flowers – while wool is a protein fibre from sheep fleece. Based on the information in this table – these natural fibres have much less embodied energy than man-made fibres. Linen requires 10MJ of energy per kg of fibre, cotton 55MJ and wool 63KG.

Viscose (similar to rayon) is a man-made fibre created from reconstituted plant fibres – making it a hybrid between natural and synthetic – and it requires 100 MJ per kg of fibre to produce.

Then there’s the jump up to polypropylene (115MJ/kg), polyester (125MJ/kg), acrylic (175MJ/kg) and nylon (250MJ/kg) which are variously made from the non-renewable resources of petroleum, coal or gas.

In the recent article, O Ecotextiles wrote that fabrics were the elephant in the room on terms of greenhouse gas emissions. It said: “In 2008, annual global textile production was estimated at 60 billion kilograms (KG) of fabric. The estimated energy and water needed to produce that amount of fabric boggles the mind: 1,074 billion kWh of electricity or 132 million metric tons of coal and between 6 – 9 trillion litres of water.” Rupp, Jurg, “Ecology and Economy in Textile Finishing”, Textile World, Nov/Dec 2008

Sew it Again is a social change project highlighting why we need to adapt our fashion habits and what actions we can take to reduce our individual clothing footprint.

When drought dramatically reduced our city’s water supply several years ago, Brisbane people reduced our water consumption dramatically. We’ve got form – we can change behaviours when we understand there’s a good reason to do it.

I believe in individual, creative dress that doesn’t harm the environment. I believe we are at the start of a refashion revolution, based on reusing clothing that already exists in the world.

I believe in individual, creative dress that doesn’t harm the environment. I believe we are at the start of a refashion revolution, based on reusing clothing that already exists in the world.

All my clothing comes from op shops, altered to suit myself using simple sewing skills I learned from the women in my family.

Today’s upcycle is Sew 314 – and started life as a long linen dress with a plain round neckline. I bought it for the lovely linen fabric, even though the style was a bit dated. To enliven it, I cut off the bottom of the dress and zigzagged it inside the neckline, so it now falls forward over the neckline as a loose collar (and covers over the zigzag stitching). To create some interest, I’ve pinned this with a vintage lapis lazuli brooch – which I repaired by gluing a new pin to the sterling silver back (the glue is not visible from the front). To finish, I turned up the new hemline and cut out the synthetic lining.

With a few small tweaks, a wash and a shake, a dated linen dress lives again. Why buy new when there is a veritable mountain of second-hand natural fibre clothing to be rescued and revived – in ways the minimize your clothing footprint?